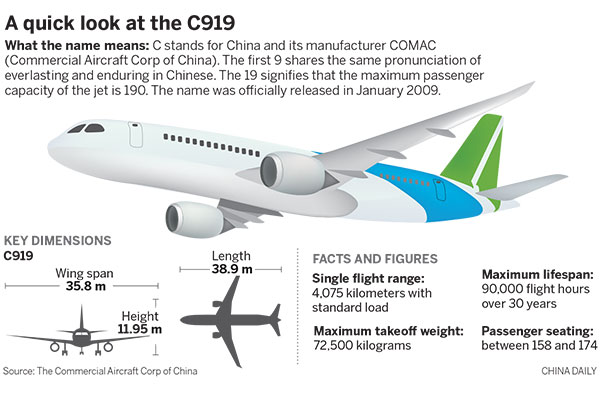

[Photo/China Daily]

China is gearing up to become a force in the global aviation market with its own large passenger aircraft. The homegrown C919 narrow-body jet has underlined the country’s ambitious commercial aviation program, and it is set to provide a major impetus to domestic airplane manufacturing.

In 2018, the C919 will enter the phase of obtaining airworthiness certification in China after achieving a number of milestones in the past year, including the successful flights of two test aircraft, among the six planned in total.

The plane is also an example of how China will further its supply-side structural reform, and make more efforts to improve economic quality, promote innovation, cut overcapacity and foster new growth drivers.

Besides, China must build and improve the mechanisms for pushing ahead high-quality development, said a statement released after the annual Central Economic Work Conference in December 2017.

“The plane has been regarded as a significant symbolic project to empower the manufacturing ability and drive the real economy of China,” said Wu Yue, deputy director of the C919 project and an assistant to the deputy general manager at the Shanghai-based State-owned Commercial Aircraft Corp of China Ltd, or COMAC, its manufacturer.

“We urgently need to establish a systematic project management system in line with international standards. Meanwhile, it has to be based on the current situation in the aviation industry and commercial aircraft manufacturing in China,” he said.

China will give fresh impetus to the Made in China 2025 strategy by implementing five key projects and bringing to life a slew of national innovation demonstration zones, according to the Ministry of Industry and Information Technology, the country’s top regulator for industrial development.

The pledge accords with Party General Secretary Xi Jinping’s call at the Central Economic Work Conference to “move Chinese industries up to the medium-high end of the global value chain, and foster a number of world-class advanced manufacturing clusters”.

Beijing has completed the top-level design of the grand plan, which is the first decade of a program of actions to marshal the country’s high-end manufacturing horsepower, said Miao Wei, minister of industry and information technology.

To shore up the ambition, continued efforts will be devoted to the setting up of a national center for manufacturing innovation, intelligent manufacturing, creation of a strong industrial base, green manufacturing and high-end equipment innovation, Miao said on the sidelines of the 19th National Congress of the Communist Party of China last October.

The manufacturing of commercial aircraft has been regarded as one of the most advanced industries globally, in terms of technologies and project management. Usually, it takes about eight to 10 years to research and develop a large passenger jet, with an investment of billions of dollars.

In 2017, China’s first homegrown large passenger jet C919, a model that is similar to the Boeing 737 and the Airbus 320, made significant breakthroughs. Ultimately, it aims to break the duopoly of Boeing Co and Airbus SE.

In May, the first prototype of the test aircraft made its maiden flight at Shanghai Pudong International Airport. In November, it completed its first long-haul flight from Shanghai to Xi’an, Shaanxi province, and is ready for various tests at Yanliang, one of the most important test-flight bases in China.

In December, the second test C919 aircraft made its debut flight, indicating the aircraft model is starting a period of large-scale experiments and test flights.

COMAC said it would send six test aircraft on test flights, and complete more than 1,000 compliance tests. An additional two aircraft will carry out ground tests, including static and fatigue tests.

The C919 boasts a global sourcing model that is similar to that of Boeing and Airbus. The model is believed to increase production efficiency and save costs, but aircraft manufacturers retain control of key technologies.

With more than 100,000 components required for the plane, more than 240 Chinese companies have served as suppliers. More than 460,000 people have been involved in its research and development, and 37 higher education institutions joined the project, according to COMAC.

Once mass production and delivery begin, it is expected to drive the rapid growth of the upstream and downstream industry chains and other high-end manufacturing sectors, such as metal materials, mechanical manufacturing, electronic information and chemistry.

So far, 785 orders from 27 clients in China and abroad have been placed for the C919. To further expand its overseas sales, the plane will need to comply with stringent global safety regulations.

A new agreement with the United States has helped pave the way to meeting those standards. In October, the Civil Aviation Administration of China and the US Federal Aviation Administration (FAA), announced they would validate the regulatory standards of both countries.

This will help shorten the C919’s review procedure in obtaining an airworthiness certificate by the FAA, although the aircraft still faces various other safety checks.

Meanwhile, China and Europe are also in the process of certifying the C919 under the China-European Union air-safety agreement.

“When we refer to a nation with strong aviation power, first it needs to have large traffic volumes, then strong manufacturing abilities, and finally the aviation regulatory standards of the country should be widely recognized,” said Lin Zhijie, an aviation industry analyst and columnist at Carnoc, China’s leading civil aviation web portal.

He added that the C919’s entry into the market is expected to take place in the 2020-2022 period.

“In the short term, the C919 aircraft won’t have a significant impact on the market share of Boeing and Airbus. But in the long term, it has the potential to be exported to more countries.”