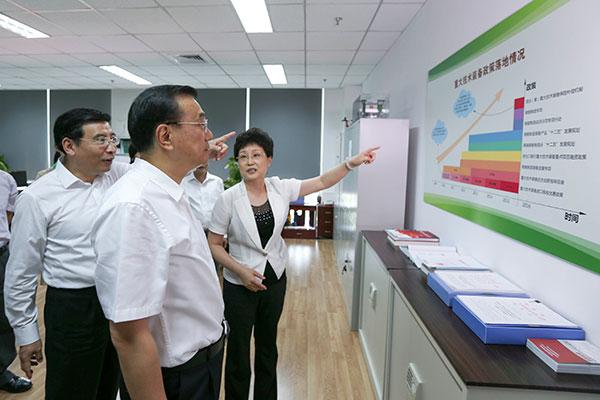

Premier Li Keqiang is briefed about the Made in China 2025 project during a visit to the Ministry of Industry and Information Technology on June 15, 2015.

Back in the 1990s, when the IBM-developed chess computer beat world champion Garry Kasparov, China only took up 3 percent of the total output of global manufacturing. Now, as the number rises to 25 percent, China can enjoy the title of “world’s top manufacturer”.

However, in Premier Li Keqiang’s eyes, “Made in China” still has large room for improvement. The “Made in China 2025” plan, first brought up in this year’s government work report, is expected to steer China’s manufacturing industry toward deep integration of informatization and industrialization in the following decade.

In an executive meeting of the State Council on March 25, the Premier called for an upgrade of manufacturing, saying it is still an important pillar of the national economy in industrialization. Moreover, at least 11 topics during the 100 executive meetings since the Premier came to office, directly relate to “Made in China”.

“The focus of ‘Made in China’ should be diverted from consumer goods to the equipment manufacturing industry to promote the upgrade of the economy to a higher level,” the Premier said at an executive meeting on June 17.

Ten years of transformation

The “Made in China 2025” plan has been considered as the first-phase roadmap that will lead the country to transform from a “large manufacturer” to a “strong manufacturer” within 30 years.

When the document was released in May, analysts soon noticed that the State Council’s executive meetings had discussed much of the content, such as enhancing financial support to “going-out” enterprises and accelerating the development of modern vocational education.

In an executive meeting on March 25, the Premier urged the government to pinpoint direction, refine standards and highlight the focus during the implementation of the guidelines.

“As long as we can make breakthroughs in certain areas, we will lay a solid foundation for the future. It takes ten years of hard work to bring ‘Made in China’ to a new height,” he said.

Premier Li presents German Chancellor Angela Merkel with a Luban Lock during his visit to Germany on October 10, 2014.

Good timing

During his visit to Germany in October 2014, the Premier presented German Chancellor Angela Merkel with a gift: a Luban Lock made by 3 Chinese students with German machine tools.

Lu Ban has long been considered as the ancestor of Chinese craftsmanship while “Made in Germany” has been the benchmark of the modern manufacturing industry. Analysts said that the gift signaled future cooperation between world’s largest and highest-quality manufacturers.

In fact, “Made in China 2025” has been constantly compared with Germany’s “Industry 4.0”, a national strategy that aims at endorsing research and innovation and is of revolutionary significance in industry.

Countries such as the United States, Japan and France also issued similar plans, seeking to regain their edge in manufacturing through technological progress and policy adjustment. Therefore, the Chinese administration introduced “Made in China 2025” at the right time.

The Premier has stressed in many executive meetings that the “Internet Plus” model and “going-out” for Chinese equipment manufacturers are two accelerators of the “Made in China 2025” plan, which also calls for an integration of modern manufacturing with the Mobile Internet, cloud computing and big data.

Key to success is ‘Made by Chinese Expertise’

Last year, the Premier told a story at an executive meeting about one of his trips to Europe ten years ago. During a visit to a company, he was surprised that metal bars made by skilled technical workers were even better quality than those made by machines.

One topic of the meeting that day was about educating millions of engineers, technical workers and professional specialists to improve competitiveness of the ‘Made in China’ model and promote economic upgrade.

“We are in dire need for such senior technical workers,” the Premier said.

With an emphasis on “innovation” and “specialists”, the Premier pointed out that the key to success for “Made in China 2025” is to advance “Made by Chinese Expertise”. At an executive meeting on June 17, he called on mass innovation and entrepreneurship to stimulate market vitality and realize the smart transformation of “Made in China”.